When the lights flicker or a plant unexpectedly shuts down, the ripple effect across the grid is palpable. For coal-fired power plants, consistent, efficient operation isn't just a goal—it's a critical mandate. Yet, the workhorse of these facilities, the coal mill, often faces a barrage of challenges that can derail performance, inflate costs, and even threaten safety. Understanding and proactively addressing these "Troubleshooting Common Coal Power Problems" is paramount, especially as advanced mill technology offers increasingly robust solutions.

This isn't about patching old issues; it's about transforming reliability. We'll dive deep into the specific pain points that plague coal milling operations and unveil how modern, sophisticated grinding and material handling systems are revolutionizing the uptime, efficiency, and environmental footprint of these essential power generators.

At a Glance: Key Takeaways for Power Plant Operations

- Wear is the Enemy: Abrasive coal rapidly degrades traditional mill components; advanced alloys extend lifespan 4-5x.

- Precision Pays: Inconsistent particle size leads to incomplete combustion and higher emissions. Modern mills offer real-time, ultra-fine control.

- Vibration is a Warning: Untamed vibrations signal deeper issues, causing costly damage. AI-driven systems and hydraulic dampeners are game-changers.

- Beyond the Mill: Don't overlook seals, gearboxes, feeders, and cooling systems—they are often silent failure points.

- ROI is Real: Investing in advanced mill technology can yield significant returns, often within 18-24 months, through energy savings and reduced maintenance.

- Holistic Approach: True reliability comes from integrating advanced materials, smart controls, and robust design across the entire grinding circuit.

The Grinding Gauntlet: When Raw Coal Meets Resistance

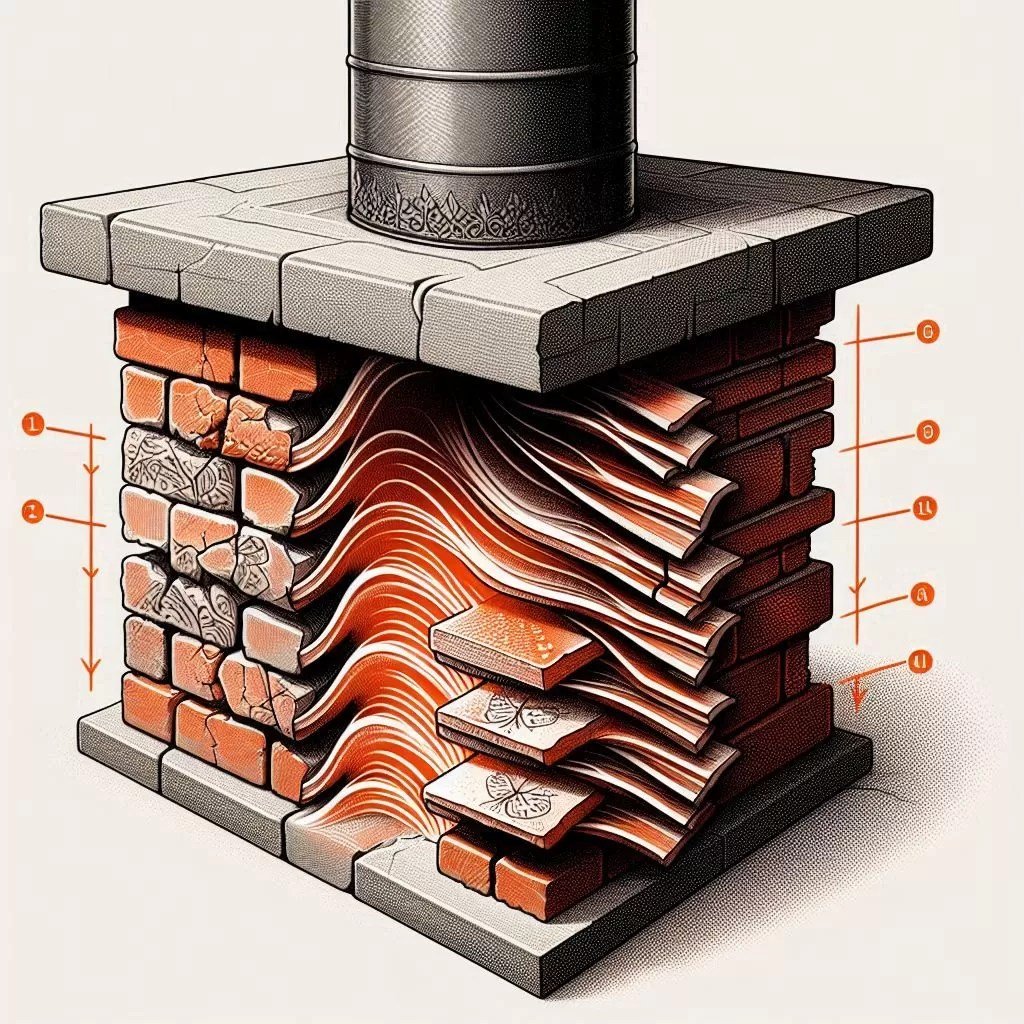

At the heart of every coal power plant is the pulverizer, or coal mill. Its job seems simple enough: grind raw coal into a fine powder, or "pulverized coal," suitable for combustion. But this process is anything but straightforward. The inherent abrasiveness of coal, coupled with variations in its hardness, moisture, and impurity content, creates a constant battle against wear, inefficiency, and operational instability.

Let's break down the most common grinding problems that power plant operators grapple with daily.

Problem 1: The Relentless March of Wear and Tear

Imagine constantly rubbing sandpaper against steel. That's essentially what happens inside a coal mill. The sheer abrasive nature of coal, especially high-sulfur or high-ash varieties, subjects grinding rollers, tables, and liners to extreme stress.

Symptoms of Excessive Wear:

- Frequent Component Replacements: Traditional mill components might need replacement every 1,500-2,000 operating hours, leading to predictable but costly downtime.

- Reduced Grinding Capacity: As grinding surfaces erode, the mill becomes less effective, struggling to process the required tonnage.

- Increased Specific Energy Consumption: A worn mill works harder to achieve the same output, driving up electricity usage per ton of coal.

- Vibration and Noise: Worn components can lead to imbalance and increased mechanical stress, manifesting as abnormal vibrations and sounds.

The Advanced Mill Solution: Materials Science Revolution

Modern mill technology addresses this head-on with superior metallurgy. For instance, the LM Series Vertical Roller Mill utilizes advanced chromium-molybdenum alloy rollers. These aren't just incrementally better; they offer a lifespan 4-5 times longer than conventional materials. Think about that: 4-5 times fewer replacements, significantly extending maintenance intervals.

Beyond just new materials, innovation extends to maintenance itself. Patented roller recovery systems allow for in-situ hardfacing, cutting replacement-related downtime by as much as 60%. This means less time the mill is offline and more time it's making power.

Problem 2: The Particle Predicament – Inconsistent Fineness

The goal isn't just to grind coal; it's to grind it right. The fineness of pulverized coal directly impacts combustion efficiency and emissions. Too coarse, and it won't burn completely. Too fine, and you waste energy.

Symptoms of Inconsistent Particle Size:

- High Unburnt Carbon in Fly Ash: If the fineness is poor (e.g., R90 > 25% for traditional mills), 3-8% more carbon can remain unburnt, representing wasted fuel.

- Reduced Boiler Efficiency: Incomplete combustion directly translates to lower overall boiler efficiency, impacting the plant's heat rate.

- Increased NOx Emissions: Inconsistent combustion can contribute to higher nitrogen oxide emissions. One plant using an MTW215G Trapezium Mill saw a 12% reduction in NOx emissions through optimized fineness.

- Burner Nozzle Erosion: Overly coarse particles can accelerate the erosion of burner nozzles, leading to further maintenance issues. Studies show fineness variations cause 1-3% efficiency drops in 72% of units.

The Advanced Mill Solution: Precision Particle Control

Modern mills employ sophisticated classification and feedback systems to maintain consistent particle fineness. The SCM Ultrafine Mill, for instance, features a vertical turbine classifier with a staggering adjustment precision of 0.1-5µm. But it's not just about fine-tuning; it's about constant vigilance.

These systems integrate real-time particle size monitoring, often using laser diffraction, and feed that data back into an automated grinding pressure system. This ensures a stable fineness, even when the coal's hardness varies significantly (e.g., HGI 45-80). Achieving R90 < 18% consistently is no longer a dream but a standard expectation, dramatically improving combustion and efficiency.

Problem 3: The Jitters and Jolts – Vibration and Instability

A mill that's shaking isn't just noisy; it's a mill under duress. High vibrations are a tell-tale sign of imbalance, inconsistent feeding, or mechanical stress, and they can be catastrophic for expensive bearings and drive systems.

Symptoms of Vibration & Imbalance:

- Excessive Vibration Readings: Any reading above 8mm/s root mean square (RMS) should trigger an alarm.

- Bearing and Drive System Failures: Persistent vibrations lead to premature wear and failure of critical rotating components.

- Unscheduled Downtime: Severe vibrations often necessitate an immediate shutdown to prevent catastrophic damage.

- Reduced Lifespan of Supporting Structures: Constant stress can compromise the integrity of the mill's foundation and support framework.

The Advanced Mill Solution: Smart Stability Systems

Modern grinding machines integrate intelligent systems designed to mitigate vibrations. Hydraulic dampening cylinders can reduce vibration amplitude by as much as 70%, absorbing shocks and smoothing operations. Even more impressive are AI-based load balancers that can predict imbalances up to 30 minutes in advance, allowing operators to intervene before a problem escalates. This proactive approach safeguards vital components and drastically cuts down on unexpected outages.

Beyond the Grinding Chamber: Unseen Threats to Uptime

While the grinding elements get most of the attention, a coal mill is a complex ecosystem. Failures often stem from seemingly minor components or overlooked auxiliary systems. Ignoring these "silent killers" can lead to increased maintenance costs, reduced lifespan, and frustrating, unscheduled shutdowns.

Problem 4: The Drivetrain Dilemma – Gearbox and Shaft Failures

The gearbox and connecting shafts are the unsung heroes, transmitting immense power under continuous load and torque cycles. They are also highly susceptible to fatigue and wear if not properly designed and maintained.

Symptoms of Drivetrain Issues:

- Unusual Vibrations or Noises: Grinding, clunking, or whining sounds from the gearbox are red flags.

- Oil Leaks: Leaks from the gearbox housing indicate seal failure or internal pressure issues.

- Shaft Misalignment: This leads to increased wear, fatigue cracks, and potential sudden breakage.

- Overheating: Elevated gearbox temperatures point to lubrication issues, excessive friction, or cooling problems.

The Advanced Mill Solution: Fortified Drivetrains

Upgrading to forged alloy steel gears and shafts, specifically heat-treated for high fatigue resistance, significantly enhances durability. These aren't just stronger; they are engineered for smoother power transmission and a much longer operational life, reducing the frequency of costly gearbox overhauls. A reliable drivetrain ensures the grinding mechanism operates at its peak, without internal stress points.

Problem 5: The Seal Scenario – Small Parts, Big Consequences

Seals might seem like minor components, but their failure can cascade into significant problems, affecting everything from lubrication integrity to fire safety.

Symptoms of Seal Failure:

- Coal Dust Leakage: Dust escaping around bearing housings or other interfaces contaminates the environment and poses fire risks.

- Oil/Lubricant Contamination: Compromised seals allow abrasive dust or moisture to enter lubrication systems, leading to premature bearing and gear wear.

- Overheating: Degraded lubrication due to contamination can cause components to overheat.

- Increased Maintenance of Nearby Components: Constant dust and contamination necessitate more frequent cleaning and inspection of adjacent systems.

The Advanced Mill Solution: High-Performance Sealing Systems

Modern mills utilize CNC-machined seal components made from high-temperature and corrosion-resistant materials. These advanced seals provide a far more robust barrier, effectively preventing coal dust leakage and protecting internal systems from contamination. By maintaining the integrity of the lubrication system, they dramatically reduce the frequency of maintenance for bearings, gears, and other critical components, contributing to the overall reliability of the mill.

Problem 6: The Flow Fiasco – Feeder and Material Handling Glitches

The coal mill can only perform as well as the system feeding it. Inconsistent or problematic material handling can starve the mill, cause blockages, or overwhelm its internal components, negating any gains from advanced grinding technology.

Symptoms of Feeder & Material Handling Problems:

- Inconsistent Coal Feed Rate: This leads to unstable mill operation, fluctuating grinding pressure, and inconsistent particle size.

- Blockages and Choking: Coal can clump or get stuck in hoppers and conveyors, reducing throughput and demanding manual intervention.

- Excessive Wear on Feeder Components: Abrasive coal also wears down feeder plates, chains, and belts.

- Increased Stress on Mill Motors and Rollers: Erratic feeding forces the mill to constantly adjust, putting undue strain on its internal components.

The Advanced Mill Solution: Smart, Heavy-Duty Feed Systems

Modern power plants recognize the critical role of material handling. This means designing and manufacturing heavy-duty feeder systems, including plate feeders with forged chains, modular belt conveyors with precisely controlled feed speeds, and specially shaped hoppers to prevent blockages. These systems ensure a stable, consistent flow of coal to the mill, optimizing grinding consistency and reducing strain on the entire grinding circuit. This level of precision is key to ensuring consistent output, much like how a Satisfactory coal generator guide emphasizes consistent fuel delivery for optimal energy production.

Problem 7: The Heat Hazard – Inadequate Cooling

High operating temperatures are an enemy to longevity for many mill components, particularly bearings, seals, and lubrication systems. Overlooked or insufficient cooling can severely shorten the lifespan of vital parts.

Symptoms of Inadequate Cooling:

- Overheated Bearings and Gearboxes: Elevated temperatures can degrade lubricants, reduce bearing life, and even warp components.

- Frequent Lubricant Degradation: High heat breaks down lubricating oils faster, requiring more frequent changes.

- Increased Component Wear: Parts operating under excessive heat experience accelerated wear.

- Automatic Shutdowns: Many mills have temperature sensors that will trigger an emergency shutdown to prevent damage from overheating.

The Advanced Mill Solution: Optimized Cooling Systems

Ensuring proper cooling is essential for maintaining component integrity and extending the mill's operational window. Advanced solutions include modular rotary coolers made from high-conductivity alloy castings and optimized annular (ring-type) coolers. These systems are designed to manage heat efficiently, often constructed from corrosion- and heat-resistant materials, thereby drastically reducing the risk of thermal failures and safeguarding critical components.

Choosing the Right Technology: What to Look For

Selecting the appropriate coal mill and associated technologies is a strategic decision that impacts the plant's long-term performance and profitability. It's not just about capacity; it's about precision, durability, and operational intelligence.

When evaluating advanced mill solutions, consider these key aspects:

- Capacity Requirements:

- For High Capacity needs (50-250t/h), look for robust vertical mills like the LM280K Vertical Mill. This type of mill typically features a powerful 1250kW main motor with a planetary gearbox, capable of processing 50-170t/h at 80-325 mesh. Integrated drying capabilities for coal with moisture content up to 25% are a significant advantage, reducing the need for separate drying equipment.

- Precision Grinding Demands:

- If Ultrafine Grinding and precise particle size control are paramount (e.g., for specialized combustion or low-emission targets), systems like the SCM1680 Ultrafine Mill are ideal. These offer capacities ranging from 5-25t/h at a fineness of D97 ≤ 5µm, often with energy-efficient 315kW main motors (offering ~30% energy savings) and quiet operation below 75dB.

- Material Durability: Always prioritize mills with components made from advanced wear-resistant alloys (e.g., chromium-molybdenum) and options for in-situ hardfacing. This directly translates to longer intervals between maintenance and lower lifetime costs.

- Integrated Smart Controls: Seek mills with real-time monitoring, automated feedback loops (for fineness and pressure), and AI-driven predictive capabilities for issues like vibration and imbalance. This automation reduces reliance on manual adjustments and improves stability.

- Vibration Mitigation: Ensure the mill incorporates effective vibration dampening (e.g., hydraulic cylinders) and load balancing systems.

- Robust Auxiliary Systems: Don't neglect the "small parts." Verify that seals are made from high-performance materials, gearboxes are forged and heat-treated, feeders are heavy-duty and consistent, and cooling systems are optimized for thermal management.

The Payoff: ROI and a More Reliable Future

The initial investment in advanced coal mill technology might seem substantial, but the returns are often compelling and swift. Power plants that have adopted these modern solutions typically see a Return on Investment (ROI) within 18-24 months.

Consider a 600MW power plant utilizing an MTW215G Trapezium Mill:

- Reduced Specific Power Consumption: A drop from 23.7 to 14.6 kWh/t represents a massive 38% energy saving per ton of coal processed.

- Extended Maintenance Intervals: Maintenance intervals stretched from 1,800 to an impressive 4,500 hours, dramatically cutting downtime and labor costs.

- Lower Emissions: Optimal fineness achieved through advanced grinding led to a 12% reduction in NOx emissions.

These examples highlight a critical truth: modern grinding systems, fortified with advanced materials, intelligent controls, and robust designs, can effectively resolve over 90% of common coal milling problems. They transform what was once a bottleneck into a highly efficient, reliable, and environmentally responsible component of the power generation process.

Optimizing for Today, Preparing for Tomorrow

The journey to greater reliability in coal power isn't about incremental fixes; it's about embracing transformative technologies. By understanding the core challenges in coal grinding and adopting advanced solutions—from wear-resistant alloys and precision particle control to intelligent vibration mitigation and robust auxiliary systems—power plant operators can significantly enhance performance. This focus ensures not only operational stability and efficiency but also extends equipment lifespan, reduces environmental impact, and ultimately secures a more reliable energy future.

The demand for consistent, affordable power isn't going away. By proactively addressing common issues with cutting-edge engineering, coal power plants can continue to be a foundational part of the energy mix, operating smarter, cleaner, and more efficiently than ever before. It's about working with the technology, not against the challenges.